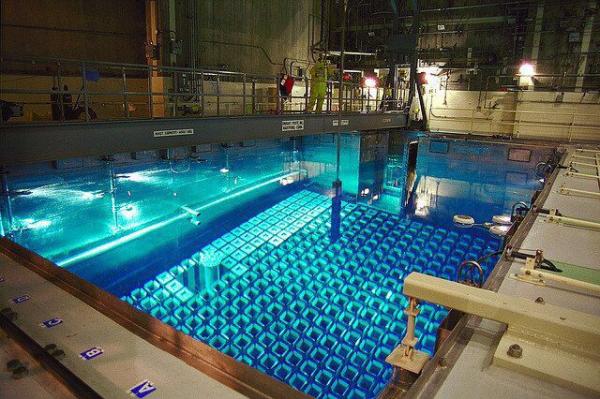

Spent fuel pool for storing spent fuel.

In a thermal power plant, a pile of coal is burned, leaving cinders. In nuclear power plants, spent fuel is discharged after slow fission reaction of nuclear fuel.

Just like a thermal power plant needs to keep adding coal, when the nuclear fuel cannot maintain a certain power, it needs to be replaced. This kind of nuclear fuel discharged from the reactor is called spent fuel. But "lack" does not mean that it is useless. Unlike the cinder left after burning coal, there are still a lot of treasures in the spent fuel. By extracting up to 96% of unburned uranium and newly generated nuclear fuel, the fuel elements needed for power generation in nuclear power plants can be rebuilt.

For China, which is about to usher in the rapid growth of nuclear power, this way of recycling uranium resources will largely solve the thirst for "nuclear fuel". According to the estimation of the International Atomic Energy Agency (IAEA), China has 1.2-1.7 million tons of potential uranium resources, and the proven reserves of uranium resources are about 170,000 tons. With the increase of nuclear power units, China’s demand for uranium resources is increasing. Statistics from the Geology and Minerals Division of CNNC show that by 2020, China is expected to have a shortage of natural uranium of up to 2,600 tons, and by 2030, this figure will climb to 10,900 tons. For the whole world, natural uranium is also in short supply.

Spent fuel reprocessing is an extremely critical link in the nuclear fuel cycle, whether from the perspective of improving the utilization rate of uranium resources, ensuring the long-term development of nuclear energy or reducing nuclear waste. However, in the face of huge demand for nuclear energy development, China’s reprocessing capacity is in urgent need of upgrading.

Extracting "Uranium" from Spent Fuel

According to the different radioactivity, nuclear waste is divided into high-level radioactive waste and medium-low radioactive waste. Among them, the spent fuel is highly radioactive, and the work clothes, gloves, abandoned and retired instruments and equipment used in nuclear power plants belong to low-level radioactive waste.

China has developed mature disposal technology for low-level radioactive waste. Both solid nuclear waste and liquid nuclear waste are solidified first, and then put into a 200-liter stainless steel barrel and placed in a near-surface repository. At present, China has built two low-level radioactive waste disposal sites: the northwest disposal site in Yumen, Gansu Province and the south China disposal site in Beilong, Guangdong Province.

The disposal of high-level radioactive waste is a worldwide problem.

A million-kilowatt thermal power plant burns about 3.3 million tons of coal every year, but a nuclear power plant with the same capacity only uses 30 tons of nuclear fuel a year, and its weight does not change much after it becomes spent fuel. Take the million-kilowatt PWR nuclear power plant as an example, which produces 25-30 tons of spent nuclear fuel every year.

Many radioactive elements in spent fuel have a half-life of tens of thousands of years, ranging from about 2.1 million years to nearly 500 years. Spent fuel will be temporarily stored in the special boron pool of the nuclear power plant before being sent to the repository.

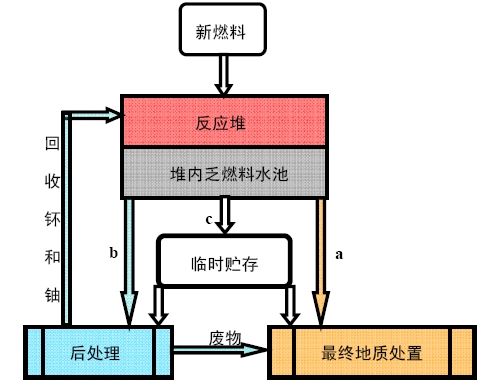

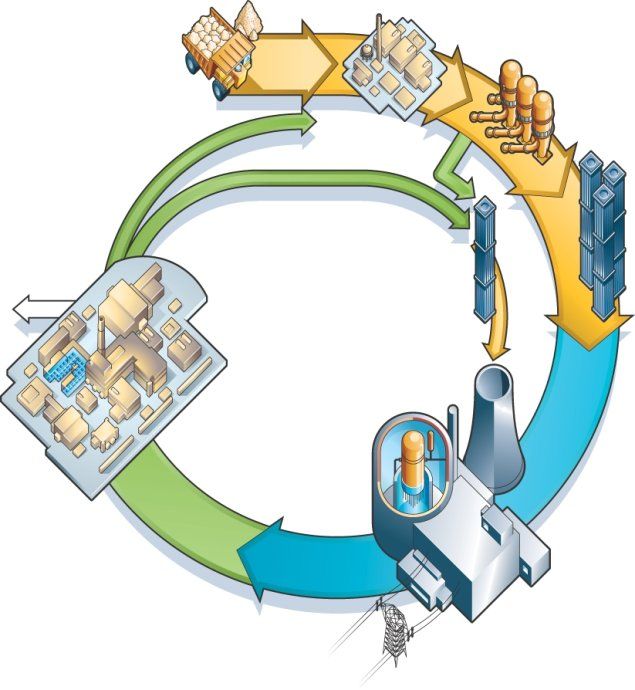

At present, there are two ways of spent fuel in the world: one is the "one-pass" open nuclear fuel cycle represented by the United States, and the spent fuel is sent to deep geological strata for disposal or long-term storage as waste after cooling and packaging; In the closed cycle adopted by Britain, France and other countries, spent fuel is stored in the spent fuel pool of nuclear power plants for 5-8 years and then transported to the reprocessing plant for reprocessing. In the post-treatment, the spent fuel is cut into small pieces, dissolved in acid, and useful uranium and plutonium are extracted and reused as fuel. The remaining waste liquid is given to a glass curing plant for curing, then put into a special waste tank and transported to a permanent disposal site for storage.

Schematic diagram of nuclear fuel cycle. In addition to countries that firmly take the road of one-pass and closed cycle, some countries choose to temporarily store spent fuel first.

Generally speaking, the utilization rate of uranium resources in PWR nuclear power plant is only about 0.6%. If the spent fuel is post-treated and the "squeezed" uranium is recycled once in pressurized water, natural uranium can be saved by 25%. If this cycle is repeated many times, the utilization rate of uranium resources can reach 1%;

If plutonium obtained from reprocessing and depleted uranium left after uranium enrichment are made into fast reactor fuel, the utilization rate of uranium resources can reach 60% to 70%.

Gu Zhongmao, former deputy director of the Science and Technology Committee of the Chinese Academy of Atomic Energy, wrote in 2011 that even according to the estimated amount of spent fuel discharged from nuclear power plants around the world at that time (about 10,000 tons/year), the "one-pass" circulation mode requires the world to build a geological repository with the scale equivalent to the Yucca Mountain Library in the United States (with a design capacity of 70,000 tons) every 6-7 years. As long as the installed capacity of nuclear power in the world doubles, it is necessary to build a geological repository every 3-4 years, which is obviously an unbearable burden.

Moreover, the spent fuel contains all radioactive nuclide heat sources, and the disposal space required for waste per unit volume is large.

In contrast, if the spent fuel produced by the million kilowatt pressurized water reactor nuclear power plant is 30 tons per year, its high-level radioactive waste can be concentrated in the glass body, and the radioactivity level will be greatly reduced, and the more "stubborn" long-lived radionuclides will be reduced.

The weakest link

For the construction of reprocessing, a Japanese expert once made such an analogy: Now many countries are building nuclear power plants, just like eating. Everyone is eating the best part now, but they don’t pay enough attention to the reprocessing of spent fuel. If this development continues, nuclear power will not be sustainable.

For China, where the scale of nuclear power construction in the world ranks first in the world, the decoupling between nuclear power plant construction and reprocessing development is particularly prominent. Up to now, there are 26 nuclear power units under construction in China, and 25 nuclear power units have been put into commercial operation, with a total installed capacity of 23.57GW (rated installed capacity, 1GW=1000MW, 1MW=1000KW, 1KW=1000W), and it has a blueprint for nuclear power development with an installed capacity of 58GW and a capacity under construction of more than 30GW in 2020.

With the construction and operation of nuclear power units, the production and accumulation of spent fuel will increase year by year. Relevant statistics show that by 2015, the total amount of spent fuel produced in China will reach 3,500 tons, and by 2020 it will reach about 10,000 tons.

At present, a large-scale commercial spent fuel reprocessing plant has not been built in China, and the first and only pilot plant for spent fuel reprocessing of power reactors in China was built in CNNC 404 plant in Gansu, and the annual processing capacity of the pilot project is far from meeting the needs of spent nuclear fuel reprocessing in China. Spent fuel reprocessing/recycling has become the weakest link in China’s nuclear fuel cycle.

France is a pioneer in the back-end industry of nuclear fuel cycle, with the largest, most mature and advanced commercial spent fuel reprocessing and recycling industry in the world, with an annual processing capacity of 1,600 tons, which not only meets domestic demand, but also provides services to Japan, Spain, Sweden and other countries.

Although the United States stopped commercial reprocessing activities for reasons of nuclear non-proliferation, it never stopped the research and development of reprocessing technology.

India started the research on reprocessing technology in 1950s, and it is the fourth country to run a commercial reprocessing plant after Britain, France and Russia, and its thorium fuel closed cycle route and fast reactor spent fuel reprocessing technology are at a relatively advanced level.

The urgency of building a large commercial reprocessing plant in China is not only due to huge practical needs, but also due to the three-step development strategy of "PWR-Fast Reactor-Fusion Reactor" in China’s nuclear power development in the long run. The fuel used in the fast reactor must be extracted from the spent fuel of PWR first. Without the reprocessing plant, the fast reactor will become an "island" and its operation will face the embarrassment of "cooking without rice". The design and construction of a large reprocessing plant is a complex system engineering with great difficulty, which spans 15 years or even longer.

"In the fast reactor nuclear energy system, the fast reactor is like a heart and the nuclear fuel cycle is like an artery." Gu Zhongmao, former deputy director of the Science and Technology Committee of the Chinese Academy of Atomic Energy, once said, "If the post-processing capacity does not go up, then the scale of fast reactors will not go up."

walking on two legs

Under the urgent situation, China’s independent development and the introduction of foreign advanced reprocessing plant technology are advancing simultaneously.

The above-mentioned CNN404 reprocessing pilot plant was successfully commissioned on December 21st, 2010, which indicates that China has mastered the reprocessing technology of spent fuel in power reactors.

Therefore, the significance of this pilot plant lies in: opening up the technological process of post-treatment of nuclear power plants; Inspect and verify the reliability and safety of equipment, instruments and meters; Accumulate design experience, operation experience and construction experience for future reprocessing plants with larger commercial scale.

In a sense, the successful hot commissioning of CNNC 404 Pilot Plant has also improved China’s bargaining power when introducing foreign post-processing technology and increased its bargaining chip.

In a reporter’s question-and-answer session in May last year, Wang Yiren, deputy director of the Bureau of Science, Technology and Industry for National Defense and deputy director of the National Atomic Energy Agency, clearly defined the path of China’s spent fuel reprocessing capacity: First, continue to improve the supporting facilities for the pilot plant, build the pilot plant into a comprehensive scientific research experimental platform, form a continuous processing capacity, and initially open up the road of closed cycle of nuclear fuel. Second, on the basis of the pilot post-treatment plant, carry out scientific research, optimize the main process, enlarge the key equipment, have the ability to independently design, build and operate the demonstration plant of spent fuel post-treatment, and rely on independent technology to build an industrial-scale post-treatment project. Third, actively carry out international cooperation, adhere to the principle of focusing on ourselves, and cooperate with China and foreign countries to build a large-scale post-treatment factory.

The key words are: independent development, Sino-foreign cooperation and walking on two legs.

In the "Longteng 2020" scientific and technological innovation plan released by CNNC at the end of 2012, a 200-ton large-scale commercial spent fuel reprocessing demonstration project with independent intellectual property rights was included in the first batch of eight scientific and technological innovation demonstration projects.

In 2013, CNNC signed a letter of intent for cooperation with Areva Group, a leading enterprise in the back end of the nuclear fuel cycle in the world, for a large-scale commercial reprocessing-recycling plant project, which will be built by adopting international advanced reprocessing recycling technology. After being put into operation in 2030, it has an annual reprocessing capacity of 800 tons of spent fuel.

At the end of June this year, witnessed by the Chinese and French prime ministers, Qian Zhimin, general manager of CNNC, and Philippe Knoche, CEO of Areva Group, signed the Memorandum of Understanding between China National Nuclear Corporation and Areva Group on the Road Map for Commercial Negotiation of Post-treatment/Recycling Plant Project Contract in Paris.

关于作者